Elevator car system is the core component of the elevator, which is the space carrier directly carrying passengers or goods. Its design and function directly affect the safety, comfort and operation efficiency of the elevator. The following is an introduction from four aspects: composition structure, core function, design requirements and development trend:

I. Composition and structure

The elevator car system is mainly composed of the following parts:

1. Car body

Cabin frame: It is composed of columns, upper beam, lower beam and other metal structures to form the support skeleton of the cabin. It needs to have enough strength and stiffness to ensure safe bearing.

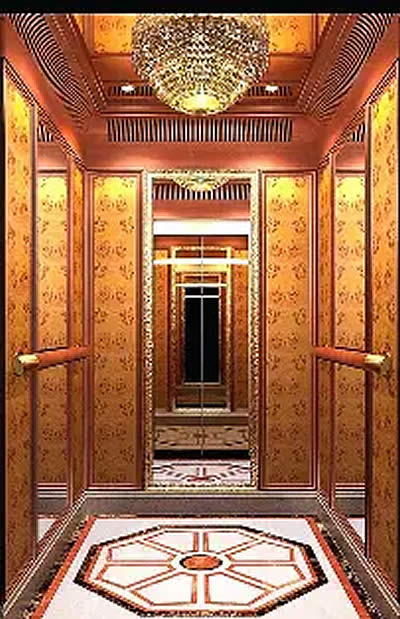

Carriage wall: usually made of steel plate, stainless steel plate or composite materials, the surface can be decorated (such as spraying, film, wood pattern plate, etc.) to improve the beauty.

Car roof: lighting, ventilation devices (such as fans or air conditioners), emergency alarm devices are installed above, and some elevators also have safety Windows (for emergency rescue).

Carriage bottom: It is composed of bearing plate and cushioning material (such as rubber pad), which is used to bear the load and reduce vibration. The floor material is usually selected from wear-resistant and anti-slip materials (such as marble, PVC floor).

2. Portal crane system

Car door: located at the entrance and exit of the car, it is divided into manual door and automatic door (most modern elevators are automatic door). It consists of door leaf, door frame, door motor and transmission device (such as belt or gear), and the opening and closing action is realized by door motor controller.

Layer door (hall door): installed at the entrance and exit of each floor, linked with the elevator door, and the safety is ensured by the door lock device when the door is closed.

3. Suspension and guidance device

Suspension device: the car is suspended on the traction machine by steel wire rope or steel belt. The steel wire rope should be combined with rope head and compensation device (such as counterweight device) to balance the weight of the car.

Guiding device: It is composed of guide rail and guide boot. The guide rail is fixed in the elevator shaft, and the guide boot is installed at the bottom and top of the car to guide the vertical and stable operation of the car and reduce the shaking.

4. Safety devices

Safety trap: When the elevator overspeed or out of control, the safety trap clamps the guide rail through a mechanical linkage device to force the car to stop and prevent falling.

Buffer: installed at the bottom of the shaft, when the car or counterweight device falls accidentally, it absorbs impact energy through hydraulic or spring structure and reduces injury.

Overload protection device: the load of the elevator car is detected by the weighing sensor. When the rated weight is exceeded, an alarm is issued and the door is closed to prevent overload operation.

5. Electrical and control systems

Operation panel: located inside the elevator car, including floor button, door open/close button, emergency call button, display screen (show floor, running status, etc.).

Sensors and controllers: the door is prevented from being caught by the light screen (infrared induction), the position of the elevator car is detected by the encoder, and the controller coordinates the actions of the door machine, traction machine and other components.

II.Core functions

1.Carrying and transportation

Secure transportation of passengers or cargo to meet rated load (e.g. 800kg, 1000kg, etc.) and rated speed (e.g. 1.0m/s, 2.5m/s, etc.).

2.Safe guarding

The door lock, safety trap, buffer and other devices are used to prevent falling, top collision, door clamping and other dangers, in line with the national standards (such as GB 7588-2003 "Elevator Manufacturing and Installation Safety Code").

3.Comfort experience

Control the vibration and noise of the car (such as shock pads, sound insulation materials), provide appropriate temperature (air conditioning system), lighting (LED lights) and ventilation.

4.Intelligent interaction

Support contactless elevator call (such as mobile APP, voice control), automatic alarm for faults, real-time monitoring of operation status (such as Internet of Things technology).

III. Design requirements

1.Safety

The structural strength shall be tested by load (such as static and dynamic load tests), and the material shall be fireproof and corrosion resistant.

The electrical system shall have leakage protection, overload protection and other functions, and meet the EMC (electromagnetic compatibility) standard.

2.Amenity

The design of the elevator space should conform to ergonomics (such as the height should not be lower than 2.0m, and the area should be adjusted according to the load), and the interior material should be environmentally friendly and odorless.

During operation, the vibration amplitude is less than 0.15g and the noise is less than 55dB (in the elevator).

3.Energy saving

Lightweight materials (such as aluminum alloy frame) are used to reduce the operating energy consumption, and energy-saving motors (such as permanent magnet synchronous motors) are used in the door machine system.

4.Usability

Special carriages are designed for different scenarios:

Residential elevator: pay attention to the beauty and space utilization, may be equipped with mirrors, handrails.

Medical elevator: spacious and flat, easy to carry stretcher in and out, using antibacterial material.

Elevator: The floor of the elevator car is strong and may be equipped with removable partitions.

IV. Development trend

1.Intelligentization and the Internet of Things

Integrate AI algorithms to implement predictive maintenance (such as monitoring component wear through sensors) and remotely monitor the status of multiple elevators through the cloud platform.

2.Green and energy saving

Popularize steel belt drive (lighter and more wear-resistant than wire rope), energy feedback technology (convert braking energy into electricity).

3.Personalized design

The interior of the elevator car can be customized (such as wood grain, art glass), and dynamic lighting effects (such as color change with floor) are supported to improve the architectural aesthetic fit.

4.Security upgrade

Non-contact door machines (such as light screen + radar double detection) are adopted, and blockchain technology is introduced to ensure that the operation data cannot be tampered with and improve the fault traceability capability.

Elevator car system is a comprehensive embodiment of mechanical, electrical and electronic technology. Its design needs to seek a balance between safety, comfort and efficiency. With the progress of technology, the future car will be more intelligent, energy-saving and personalized, providing users with better vertical transportation experience.