History of development

In 1853, at the World's Fair held in New York's Crystal Palace, American Elihu Graves Otis first unveiled his invention to the world. Standing on a platform filled with goods, he ordered his assistant to lift the platform to a height visible to all spectators and then signaled for the assistant to cut the cable of the elevator with an axe. Surprisingly, the elevator did not fall but remained firmly suspended in mid-air —— the safety device invented by Mr.Otis worked. "All is safe, gentlemen," Mr.Otis waved to the crowd below as he stood on the elevator platform. No one could have imagined that this was the first safe elevator in human history.

The history of humans using lifting tools to transport goods and people is very long. As early as 2600 BC, the Egyptians used the most primitive lifting system when building the pyramids. The basic principle of this system has remained unchanged: as a counterweight descends, the load platform rises. Early lifting tools were primarily powered by human labor. In 1203, a crane powered by donkeys was installed in a monastery along the French coast, marking the end of the era of manual lifting.

After British scientist James Watt invented the steam engine, cranes began to use steam as their power source. Soon after, William Thomson developed a hydraulic lift, using water as the medium for hydraulic power. Building on these lifts, generations of innovative engineers have continuously improved crane technology. However, one critical safety issue has never been resolved: if the cable of a lift breaks, the load platform will inevitably crash.

Mr.Otis's invention completely rewrote the history of human use of elevators. Since then, riding in elevators has ceased to be a "game for the brave," and elevators have been widely applied around the world. In December 1889, the American Otis Elevator Company produced a true elevator, powered by a DC motor, which drives a worm gear reducer to wind the rope on the drum, suspending and raising the car. In 1892, the American Otis Company began using button-operated devices, replacing the traditional method of pulling ropes inside the car, marking the beginning of modern control methods.

Life continues, technology advances, and elevators improve. Over 150 years, elevator materials have evolved from black and white to color, and designs have shifted from vertical to inclined. In terms of operation and control, innovations have been constant: handle switches, button controls, signal controls, group selection controls, human-machine interaction, and more. Multiple elevators can now be controlled in parallel or through intelligent group control. Double-decker elevators demonstrate the advantages of saving shaft space and enhancing transportation capacity.

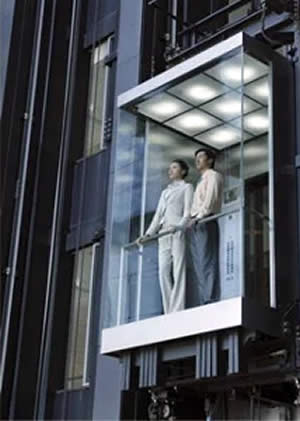

The introduction of variable-speed escalators and moving walkways has significantly reduced pedestrian travel time. Visually diverse elevators, such as fan-shaped, triangular, semi-diamond, semi-circular, and full circular models, provide passengers with unobstructed views. Leading companies like Otis Elevator in the United States showcase their unique styles, continuing to develop new elevator models and continuously improving maintenance and service systems.

Features like frequency modulation door control, smart remote monitoring, energy-saving motors, low-noise durable control cabinets, and eco-friendly composite steel belts have led to the emergence of new elevators that integrate the latest research achievements in mechanics, electronics, and optics. These innovations bring warmth and humanity to cold buildings, making people's lives better.

The development prospect of elevators in China

As competition in the elevator industry intensifies, mergers and acquisitions among large elevator companies and capital operations have become increasingly frequent. Domestic leading elevator manufacturers are paying more attention to market research, especially in-depth studies on the development environment and changing customer demand trends. As a result, many outstanding domestic elevator brands have rapidly emerged, gradually becoming leaders in the industry!

The vast market space has made the industry one of the earliest sectors to attract foreign investment. Major global elevator companies have established wholly-owned or joint ventures in China. The entry of these foreign brands has brought international technical standards, management concepts, and business models to the industry, enabling domestic elevators to quickly join the ranks of international players. From an industrial layout perspective, the domestic elevator industry exhibits significant clustering effects, with manufacturing bases for complete elevators and components mainly concentrated in the Yangtze River Delta and Pearl River Delta regions. Apart from high-end elevator components, elevator parts have largely been localized.

The rapid economic development and the continuous advancement of urbanization are the primary drivers of elevator demand growth. Historical data regression analysis shows a high correlation between real estate investment and elevator demand. Influenced by national policy adjustments, the growth rate of commercial real estate investment may slow down. However, during the 14th Five-Year Plan period, the construction of 8.7 million units of affordable housing will increase the demand for elevators. Additionally, extensive public infrastructure construction, energy-saving renovations, and exports will boost China's elevator production. According to analysis and forecasts by Qianzhan Network, China's elevator production is expected to exceed 1.5 million units by 2025, with a conservative growth rate of around 5%.

The traction machine, the heart of an elevator, after undergoing technological advancements such as planetary gear transmission, helical gear transmission, and worm gear transmission, saw the emergence of permanent magnet synchronous traction machines at the end of the 1990s. With its advantages of small size, low loss, and energy efficiency, it was rapidly promoted and has since become the mainstream model of new traction machines.

Elevator traction machines mainly include permanent magnet synchronous traction machines and traditional asynchronous traction machines. According to predictions by the China Elevator Association, China's elevator production will continue to grow steadily over the next few years, with an annual growth rate of 15-20%. With the continuous development of technology and the implementation of energy-saving policies in China, the proportion of energy-efficient elevators in total production is increasing, rising from 50% in 2016 to around 90% by 2024, reaching approximately 1.3 million units. To support the implementation of national building energy-saving policies, local governments have introduced plans for elevator replacement or renovation, replacing or upgrading elevators that need replacement due to their expiration to energy-efficient models.

Therefore, the future market demand for energy-saving elevators mainly includes three aspects: first, new demand; second, replacement of old elevators; third, energy-saving renovation. According to the prediction of the China Elevator Association, from 2016 to 2026, the demand for energy-saving elevators in China due to new demand and the replacement of old elevators.

The demand for energy-saving elevators in our country is substantial, with a strong growth trend. The compound annual growth rate from 2018 to 2024 reached 10.27%, significantly outpacing the overall growth rate of elevator demand in our country. High-performance neodymium-iron-boron permanent magnet materials, as core components of energy-saving elevator traction machines, have seen their market demand grow rapidly alongside the development of energy-saving elevators. Each energy-saving elevator requires approximately 6kg of high-performance neodymium-iron-boron permanent magnets. By 2024, the energy-saving elevator industry in our country will need to use 15,000 tons of high-performance neodymium-iron-boron permanent magnets.